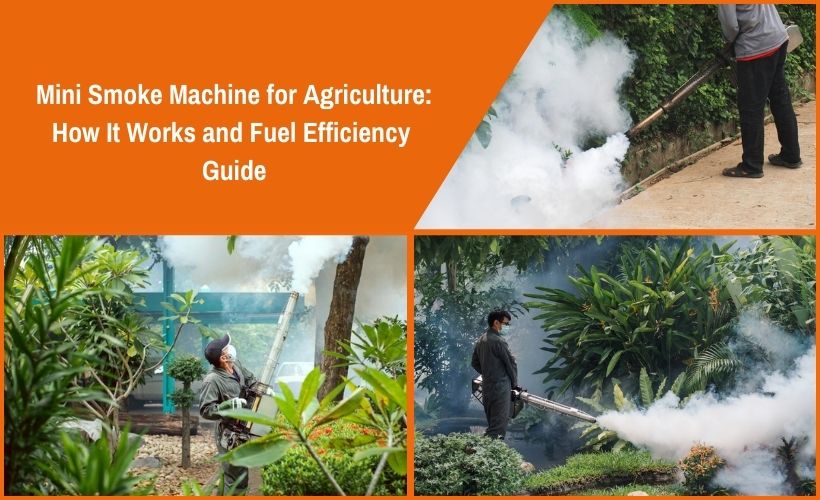

In the competitive world of modern agriculture, efficiency can mean the difference between a bumper harvest and a disappointing season. While traditional liquid sprayers have been used for decades, they often fall short due to chemical wastage, high labor requirements, and uneven coverage. This is where the mini smoke machine, commonly known as a thermal fogger, is changing the game.

Once limited to professional pest control services, mini smoke machines are now widely adopted by small-scale farmers, greenhouse operators, and commercial growers. With rising awareness about precision farming and increasing concern over fogging machine price india, farmers are recognizing the long-term cost savings and efficiency these machines offer. This guide explains how thermal fogging works, why it is more efficient, and the many practical applications that make it an invaluable agricultural tool.

Unlike conventional sprayers that rely on pressure to push liquid through a nozzle, a mini smoke machine uses thermal energy to create ultra-fine fog particles.

The Working Process

A typical thermal fogger consists of:

- A fuel tank

- A chemical solution tank

- A heating coil

The fuel—usually butane or petrol—heats the coil to extremely high temperatures. When the chemical solution (often an oil-based carrier mixed with pesticides or fungicides) passes through the hot coil, it instantly vaporizes. As this vapor meets cooler air outside the machine, it condenses into a dense, visible fog.

Thanks to their compact design, many farmers now prefer a portable fogging machine, as it allows easy movement across fields, greenhouses, and storage areas without heavy labor.

Why It Outperforms Traditional Sprayers

The key advantage lies in particle size. Traditional sprayers produce droplets ranging from 100 to 400 microns, which settle quickly on the ground. In contrast, thermal foggers generate particles as small as 0.5 to 30 microns. This “dry fog” remains suspended in the air for up to 30 minutes, allowing it to penetrate dense plant canopies and reach the undersides of leaves—where pests and fungal spores often hide.

Fuel Efficiency and Smarter Chemical Use

Many farmers assume smoke machines are costly to operate, but in reality, they are highly efficient when used correctly.

Fuel Consumption

Most mini gas-powered foggers consume about 225 grams of butane per hour. A single canister can be sufficient for multiple treatments in a medium-sized greenhouse.

Chemical Savings

Because fogging provides complete coverage with minimal liquid, growers can reduce water usage by up to 90% and significantly cut down on chemical concentrate compared to high-volume spraying.

The Importance of Pre-Heating

Always allow the machine to pre-heat for 2–3 minutes. If the heating coil is not hot enough, the solution will not vaporize properly, causing wet droplets to spit out. This wastes chemicals and may damage plant leaves.

Best Fogging Schedule to Prevent Fungal Crop Diseases Before They Spread

Fungal diseases such as Botrytis (Gray Mold) and Powdery Mildew can spread rapidly and destroy high-value crops if not managed proactively. With thermal fogging, timing is more critical than the chemical itself.

The Dawn and Dusk Strategy

Fogging works best during temperature inversions, which usually occur at dawn or dusk. At these times, cooler air near the ground traps the fog under a natural “ceiling,” preventing it from drifting away and ensuring full crop coverage.

A Preventive Approach

Rather than reacting to visible symptoms, follow this preventive schedule:

- Before high humidity or rainfall: Fog 24 hours in advance if wet conditions are forecast for more than two days.

- After pruning or harvesting: Fog immediately to protect fresh plant wounds from airborne spores.

- Regular rotation: During peak growing seasons, fog every 7–10 days while rotating fungicide classes to prevent resistance.

7 cool uses of fogging machine for mosquito Beyond Pest control

Although many people associate foggers with urban pest control, a fogging machine for mosquito management is just one of its many applications. Mini smoke machines are remarkably versatile and can also be used for:

- Greenhouse Humidification

Fogging with distilled water helps raise humidity levels quickly without overwatering soil. - Frost Protection

A fog layer can act as a thermal blanket, trapping ground heat during light frost conditions. - Livestock Sanitization

Food-grade disinfectants can be fogged into poultry houses or barns, reaching areas that manual cleaning misses. - Odor Neutralization

Fogging neutralizes airborne odor molecules in storage facilities, basements, and animal housing. - Aerosol Vaccination

In poultry farming, thermal foggers allow birds to inhale vaccines, ensuring uniform flock coverage. - Silo and Grain Bin Disinfection

Fogging kills dormant mold spores before new grain is stored, reducing the risk of aflatoxin contamination. - Emergency Indoor Sanitization

Ideal for rapid disinfection of workshops, warehouses, and community spaces using approved sanitizers.

Conclusion

The mini smoke machine is a powerful, high-efficiency agricultural tool that combines precision, portability, and versatility. By understanding the principles of thermal fogging and following a well-planned preventive schedule, farmers can reduce chemical costs, improve disease control, and significantly boost crop productivity.

When used correctly, thermal fogging is not just an alternative to traditional spraying—it is a smarter, more sustainable solution for modern agriculture.

Frequently Asked Questions (FAQs)

Q1. Is a mini smoke machine safe for crops and greenhouse plants?

Yes, a mini smoke machine is safe for crops when used correctly with approved pesticides, fungicides, or disinfectants. The ultra-fine dry fog ensures even coverage without soaking leaves or soil. It is important to follow the recommended chemical dosage, pre-heat the machine properly, and fog during suitable times such as dawn or dusk to avoid plant stress.

Q2. What factors affect the fogging machine price in India?

The fogging machine price in India depends on several factors, including fuel type (butane or petrol), fog output capacity, build quality, brand, and additional features such as portability and safety valves. While high-quality machines may have a higher upfront cost, they usually offer better durability, lower chemical consumption, and long-term savings for farmers.

Q3. Can a portable fogging machine be used for mosquito control and farm sanitation?

Yes, a portable fogging machine is widely used for mosquito control as well as agricultural and indoor sanitation. Its ability to produce fine fog particles allows it to reach hidden spaces, making it effective against mosquitoes, fungi, bacteria, and airborne pathogens in farms, greenhouses, storage areas, and livestock sheds.